January 31, 2022

Sigh, the well, even after fracturing wasn’t doing very well. It was only producing about 100 gallons a day, which meant pretty severe water rationing was needed. Showers, clothes washing, swimming pool top offs, any major use of water had to be planned for.

Time to do some research and figure out what could be done. The formal name of the subject we were researching is “Well Inflow Performance”. In 1856 the French hydraulic engineer Henry Darcy published an equation for calculating flow through a porous medium. Production Technology’s page is a great resource and the following discussion comes from there.

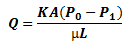

Darcy’s general equation:

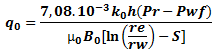

Solved for the radial flow geometry that a well has:

q0 = Flow rate

h = Effective feet of pay zone

Pr = Reservoir pressure

Pwf - Pressure in the wellbore

re = Drainage pressure, back pressure on the pump

rw = Wellbore radius

B0 = Formation volume factor

k0 = Effective permeability

μ0 = Average viscosity of the fluid being pumped

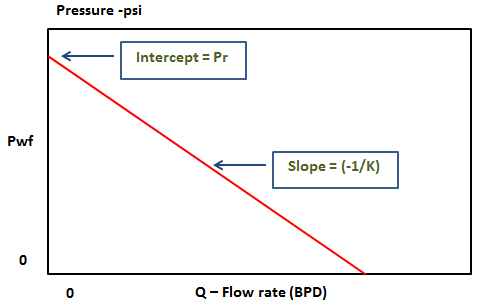

Well, that looks awful and, since we can’t actually measure very many of the variables, pretty useless. But we aren’t asking all the questions that equation can answer, we’re only asking one question - how do we increase the productivity of the well? We’ve already fractured it, we’re pumping water and so on. The only thing we can change is the pressure in the wellbore, which by reducing the pressure against the reservoir will increase the flow into the well. So everything in the above except Pwf is constant and we get:

q0 = K(Pr - Pwf)

Plotting that:

We don’t know K, of course, so we can’t say how much lowering the pump will increase the production of water, but we know that it will. We know that during construction, when the well wasn’t being pumped for long periods of time, the water level rose to only 300’ down. This is called the “Static Level” of the well. The pump was originally set at 780’ down, so it had about 480’ of water above it. We decided to approximately double the depth of the pump. This required adding 500’ of galvanized pipe and a bigger pitless adapter to handle the greater weight of pipe and power cable.

The pitless adapter allows the water pipe to the house to be joined to the pipe down the well to the pump below frost depth. One part of it is attached to the well casing, the other to the downhole pipe.

Here’s part of the existing downhole PVC pipe pulled out and laid down on the snow. They have to pull everything out because the pump is being upgraded from 1.5 hp to 3 hp to handle the greater depth. That also required new wire and copper prices were so high that it cost $10,000 for it. That was the single most expensive line item in the whole job. Mike of John’s Well Service had never seen anything come in more expensive than labor!

The new galvanized pipe is on the roof rack of the left truck. The right truck is the rework unit.

Here’s how the pipe is pulled out of the well. Putting back in is done the same way. The black flexible cable is the electrical cable that powers the downhole pump.

Did it work? Oh, yes! The production increased over four times! For this well, the slope in the graph was 4. We can now pull over 400 gallons a day out of the well, so we can use as much water as we want!