November 2, 2022

Installation of the Generac backup generator. As we found out, there is no such thing as a short power outage here. I talked to the Poudre Valley REA lineman when he was out inspecting the lines during the last, 4 hour long one and he explained the problem. If the automatic reclosers don’t work after a trip, then they’ve got to send someone out to inspect the line. Since we’re about an hour from the nearest Poudre Valley yard, that’s pretty much the minimum power outage.

Well, ok, we decided that if we had more than two 4-hour outages in a year, we’d install a backup generator. The next outage happened a couple of months ago and it lasted for 12 hours! It was time and with all the green nonsense it’s only going to get worse. Wind and solar simply don’t work. I’ll do a lengthy exposition on why eventually, but let's get on with the installation.

The installation actually took place over a couple of months, since 3 trades were involved:

The plumber for the propane supply to the generator

The electrician to supply and hook up the generator

The landscapers, who are really good at concrete work.

The existing pad for the HVAC compressor wasn’t big enough, so Doug had the landscapers, who were working up here at the time, extend it. They drilled holes in the existing pad to drive rebar pins in to lock the new pad, which will be poured into wooden forms around the current pad.

There also weren’t enough holes from the outside into the lower mechanical room for the propane supply pipe, the irrigation water, the low voltage control lines from the Generac to the transfer switch, and the power lines from the Generac to the transfer switch. They were able to do three hookups that we needed at the same time. The propane to the Generac and fire pit and the irrigation water were all hooked up today.

So KH plumbing drilled not only the hole they needed for their propane supply line and irrigation water line but also the holes Dennis the electrician needed. They did this using the drill (above) that they temporarily anchored into the wall.

Drilling through 8 1/2” reinforced concrete is not easy. Especially since Ian, the structural engineer, specified that it be a minimum of 5,000 psi concrete, which is really, really tough concrete. Korey and company knew how to handle this tough job! They use a 3” diamond coring bit rather than actually trying to remove that much concrete.

Here’s one of the cores that I kept. The wall is actually just a bit thicker than 8 1/2”. I like how the diamond coring bit just drilled through the aggregate without knocking any loose.

Here’s the overall view of all the stuff that’s needed to make everything work! The plumbers ran 1 big 1 1/4” propane line out from the lower mechanical room and teed it off to the fire pit and Generac. The pad is still wet from the coring operation. The electricians wires aren’t in yet.

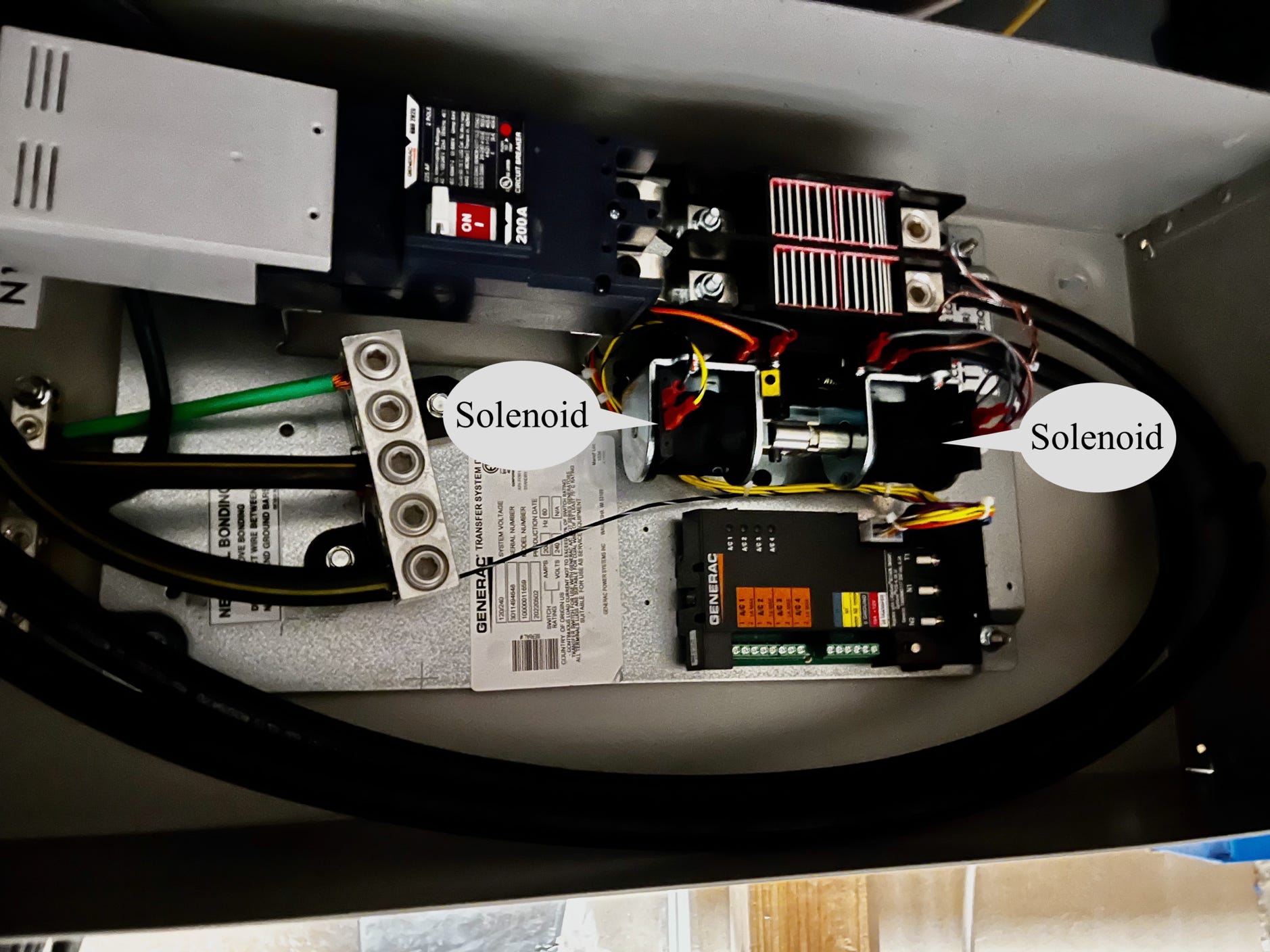

The actual brains of the backup power system, the transfer switch. The black box with “Generac” on it is the microcontroller. It detects a power failure and if it lasts longer than about 30 seconds, it starts the generator. Once the generator frequency is a solid 60 Hz, it actuates those big solenoids to switch us from line power to the generator. When it detects that the line power is back and stable again it throws the transfer switch back to line power. Those large solenoids are powerful enough that the switch only takes 2-3 cycles or about 40 milliseconds. That’s so fast that the computers stay up thru the switch over, so we can reboot them as soon as we’re on backup power.

The Generac is on the wifi, so it calls home to the mother ship when power fails. This is what we got in the first power outage about a week after installation on 11/18/2022 at 4:14:00 pm.

Power was restored almost exactly an hour later at 5:13:42 pm

Here’s the message it sends at the start of the every two week test

Here’s the start of an exercise. This was shot on 7/18/2023.