September 12, 2025

The second day of elevator assembly. Lots of unboxing and planning today.

Again, many shots had to be taken during the weekend because the site was so crowded with both the electricians and elevator people up today.

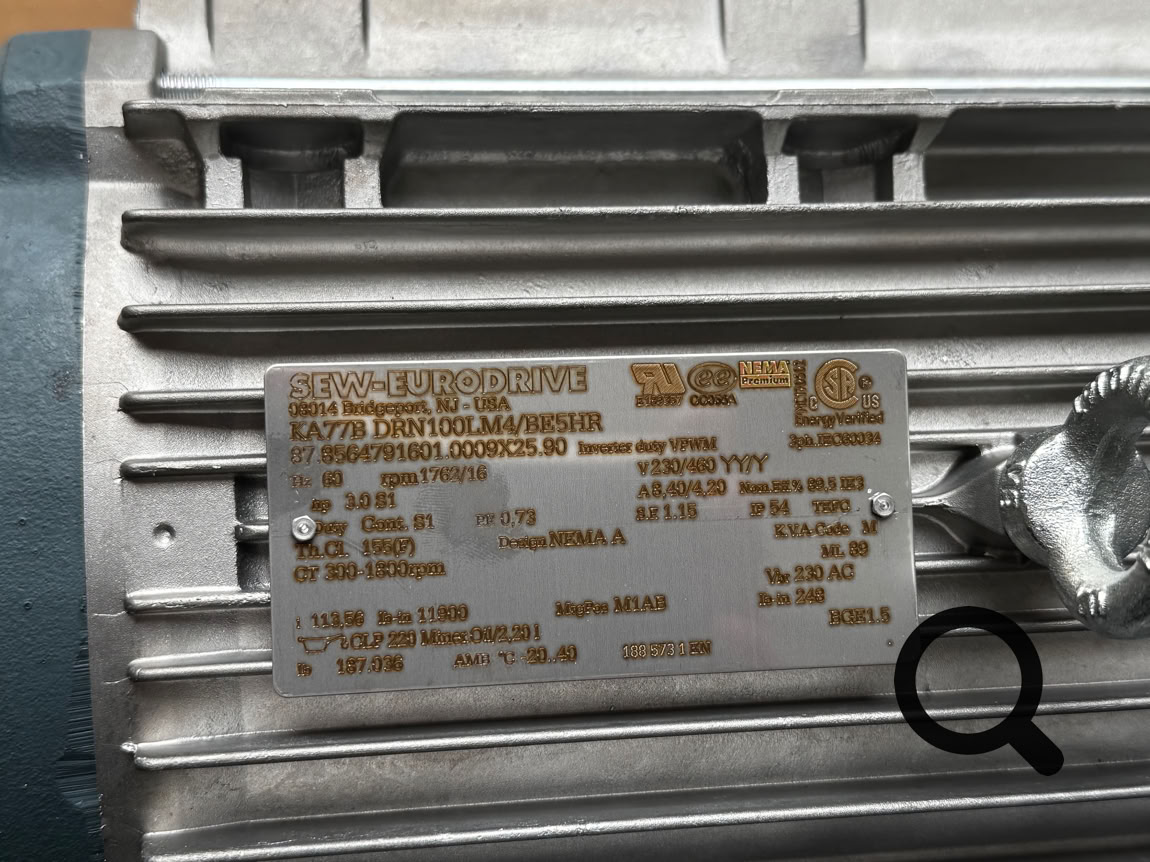

Here’s the really difficult piece - the motor and transmission.

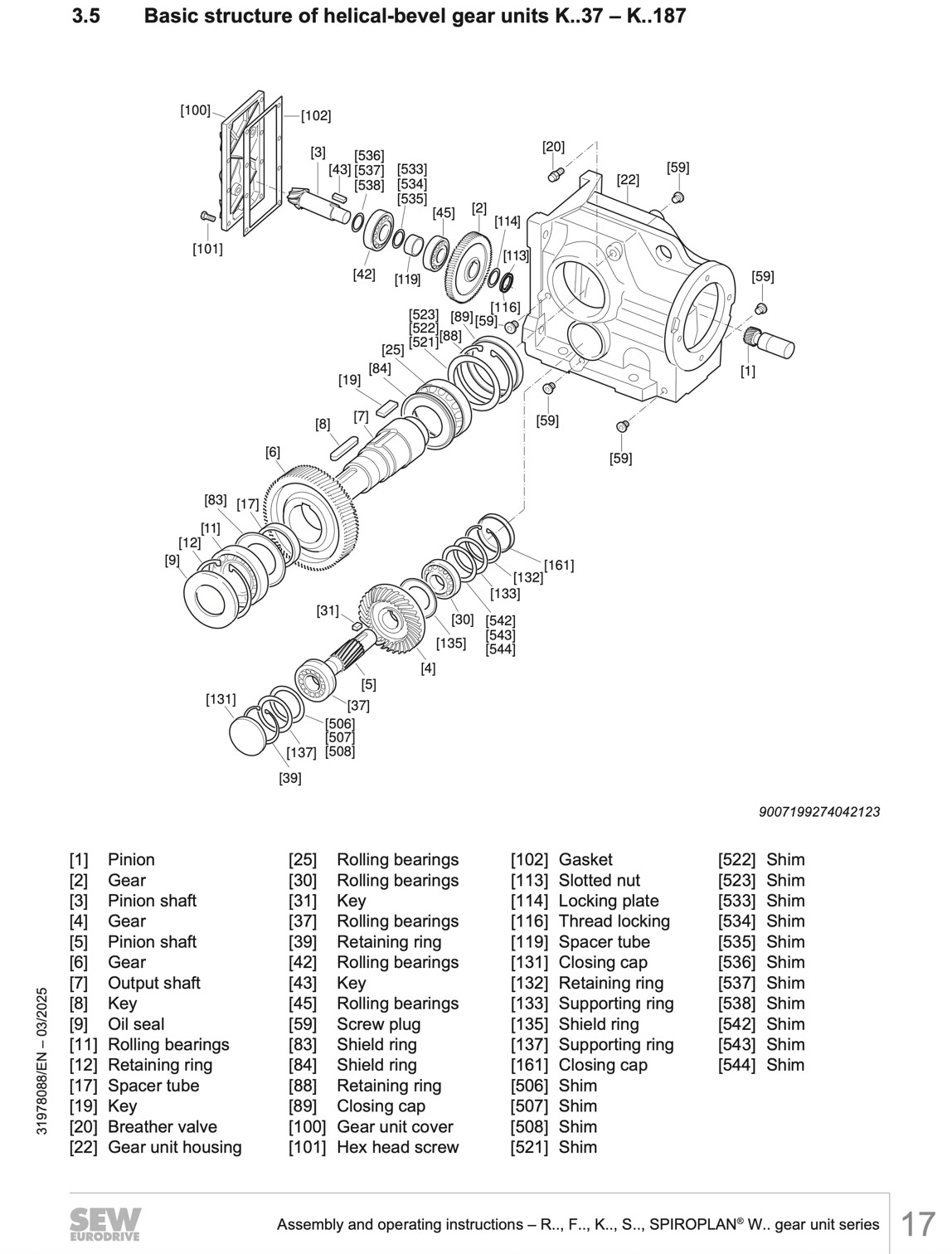

This is what’s inside the gear box. Martin suspects that no one gearbox has all of this, this is a whole bunch of different K series units combined into one sketch.

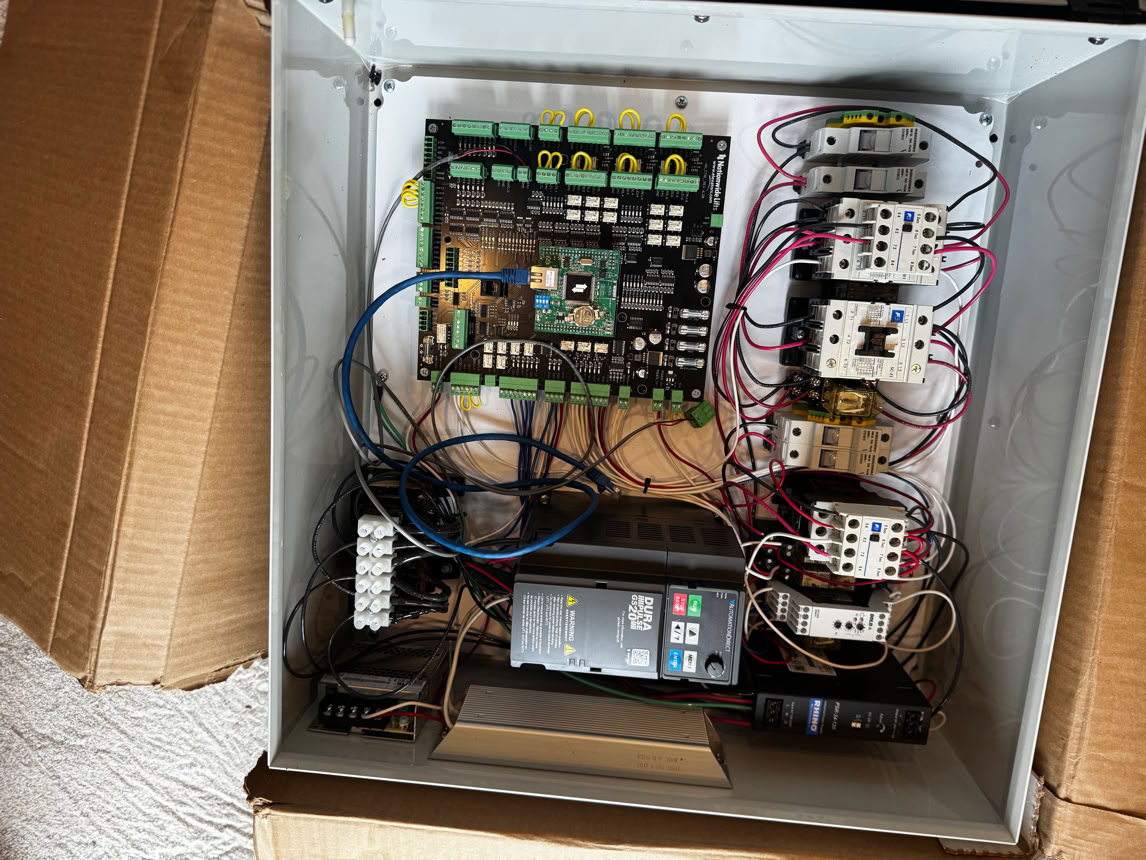

Nationwide Lifts’ control box. Yipes! This one can handle up to 6 floors, which is why there are all those yellow jumpers in the terminal strips on top. Those are telling it that the call buttons on floors 3-6 are not being pushed.

Wow! There’s a lot of data crammed into this little name plate.

The manufacturer is SEW-EURODRIVE in Bridgeport New Jersey 08014.

Oddly enough (this took a while for Martin to figure out) they put the model number of the gearbox first, its a KA77B Helical-bevel gearbox

The motor model number is DRN100L M4/BESHR, the serial number of the unit is 87.8564791601.0009X25.90.

Its a 3.081 hp, 3 phase Y connection motor that is specified for Inverter Duty VPWM (Variable Phase Width Modulation) from 300 to 1800 RPM.

We’ve only got 240 volt one phase, but the Nationwide Lifts controller takes care of this.

Finally, the assembly weighs 187.036 pounds!

The gear box has it own nameplate, but, oddly enough has the same serial number as the motor. There are a couple more bits of data on it, this wants ISO 220 Oil, which is standard 90 weight gear lube. It also can deliver up to 13,700 inch-pounds or 1141 foot-pounds of torque.

They’ve put a temporary work platform on the upper floor. In front of that is the motor mount, it’s 1/2” thick steel and weighs 63.2 pounds. We used Bill’s bathroom scale.

This is looking up at the smurf tubes at the top of the shaft. They run from the control box in the lower floor south guest bedroom to here.

The smurf tubes are routed through the northwest wall of the shaft

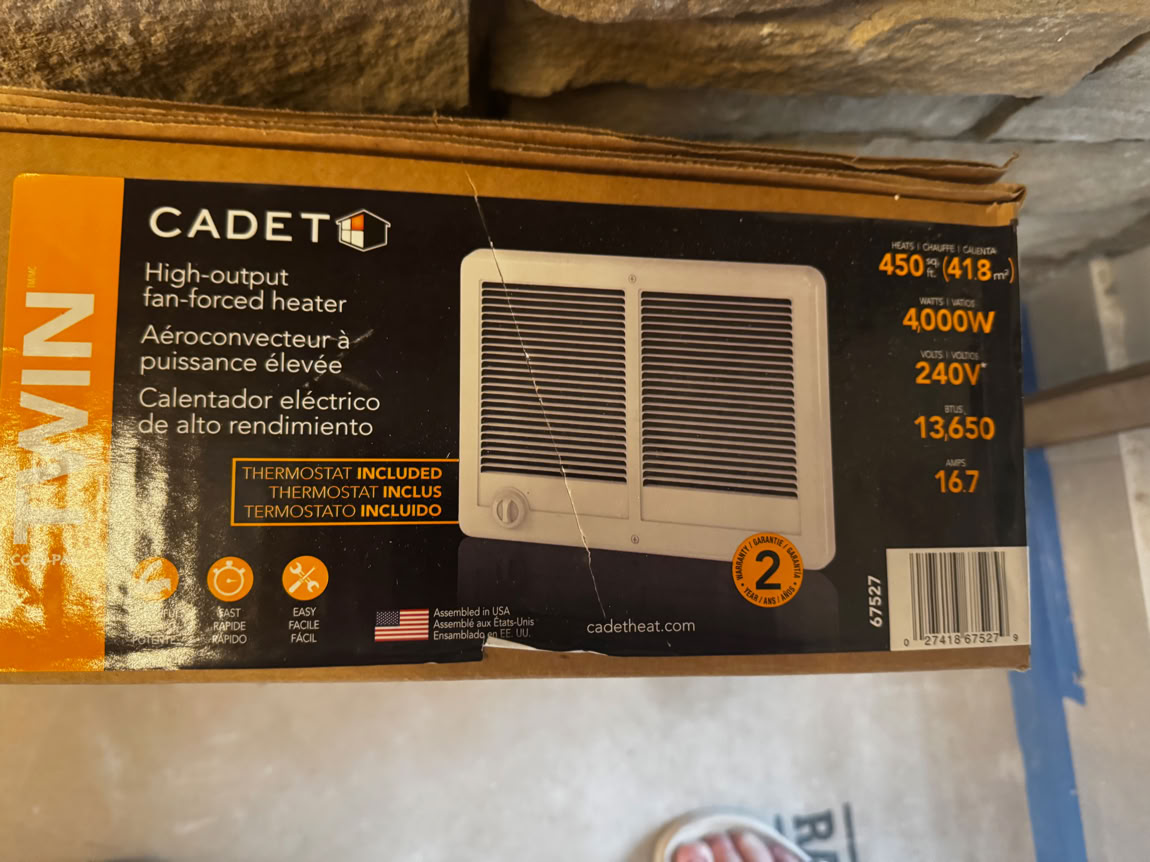

Everybody was concerned that the shaft might get too cold during the winter, so this is where the inwall 4KW electric heater will go.

The heater.