12/05/2019

Between Thanksgiving and a storm that dumped about 16” over most of the front range, there wasn’t an onsite last week! We can see how the floor joists are held up. The key to the neat system used to fasten wood to metal is a Hilti DX2 explosive gun which friction welds the “nail” to the steel and does it neatly enough that the steel does not need to have its corrosion resistant coating repaired.

All of the steel that was brought up has now been placed. The two pieces marked by the red circles form the cantilever for the office. The one in yellow is the east support of the east master bedroom’s deck.

The Hilti gun in action! You can clearly see the office cantilever structure here.

Some of the floor joists being placed. They’re quite light, so they can simply be placed by hand.

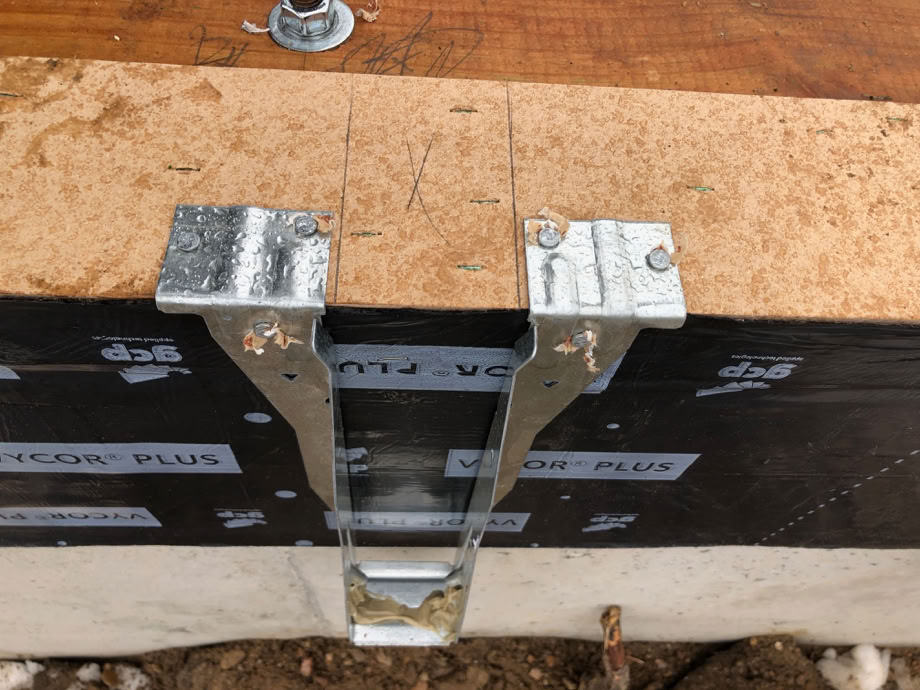

Here’s the joist hangers from below.

A bit of glue is placed wherever wood rests on steel. This keeps the floor from squeaking.

Here’s a close up of both LVL beams (the top two) and LVL floor trusses. Those beams are 2” thick and have 15 laminations in them. The floor trusses have small LVL beams as their top and bottom and oriented strand board as their web section.

The east master bedroom’s east deck support beam from below.